|

|

|

|

Compañía Noticias

Mechanical Lifespan Influencers of RF Coaxial Connectors -Elite Electronics

The mechanical lifespan of RF coaxial connectors depends primarily on three key factors: the wear resistance and fatigue resistance of contact components, the stability of structural design, and the durability of materials and coatings. Details are as follows:

Tiempo del Pub : 2025-12-25 13:35:05

>> Lista de las noticias

Contacto

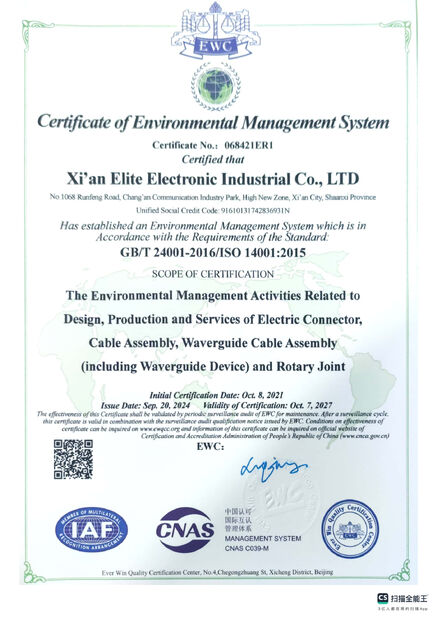

Xi'an Elite Electronics Co., Ltd.

Persona de Contacto: Ms. Elite

Teléfono: +8613609167652

Envíe su pregunta directamente a nosotros